Cobot workstations with Fanuc cobot arm

Our Cobot workstations are based on a Fanuc cobot arm. These are versatile, collaborative, industrial cobot arms with both a high payload capacity (10, 20 or 25kg) and a long reach (1249, 1418 or 1889mm), making them very suitable for palletising, case packing and other pick & place actions. For example, the cobot workstation in palletising version can handle a wide variety of products, such as (open or closed) cartons, trays, buckets or crates.

Thanks to its sensitive and smart sensors, the cobot arm knows immediately when contact takes place with a person, after which it immediately stops. The workstation is restarted by simply pressing the “resume” button and continues the work.

With our cobot workstations, you are assured of an employee who can work 365 days and 24/7. For example, palletising is physically challenging for human workers due to its monotony and physical intensity. Our cobot workstation can support the workers by taking over this task.

Specifications of the three different workstations we have currently available, you can find further down this page.

Grippers

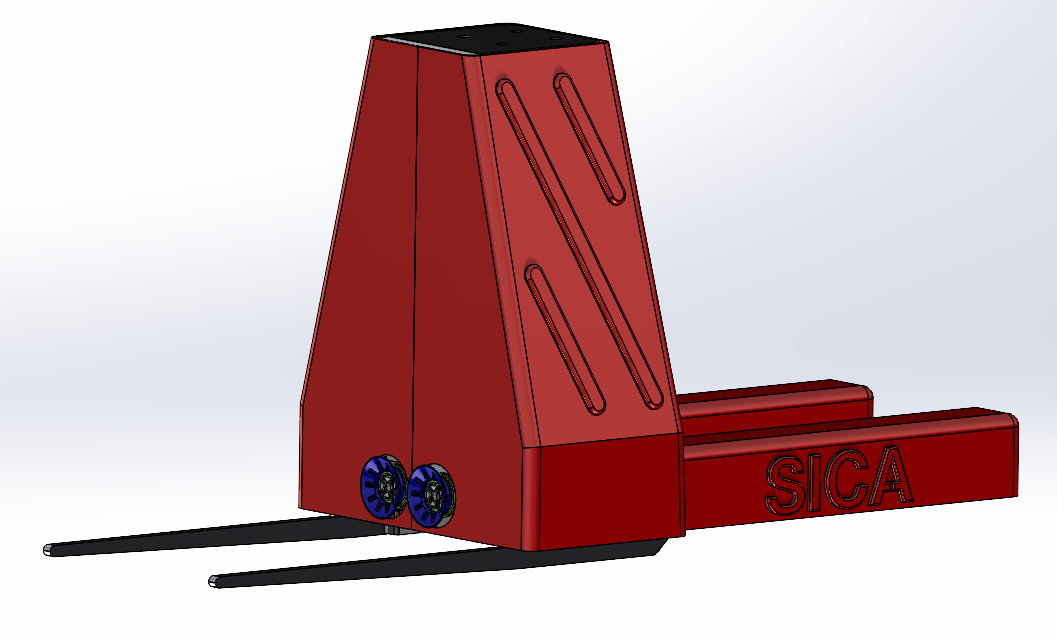

The cobot arm is standard equipped with one 3-D printed gripper, a vacuum, angle or fork gripper, which is designed and produced in-house and can be customised in your company colour. If a special gripper is needed for a specific product that can not be handled by our standard grippers, we can design and print a custom gripper with our 3-D printer.

Options

Production Insight Tool: with the Production Insight Tool, where the achieved KPI’s of the cobot workstation are displayed, you always have insight into the output of your production.

Intermediate Sheet magazine: if required, the cobot workstation can be equipped with a fixed or movable intermediate sheet magazine.

Product infeed: the cobot workstation is available with a formation unit.

Safe and easy to work with

It is important that operators can work well with our cobot workstation. For this purpose we developed a drag-and-drop tool. With this tool it is easy to add or edit box programs so you have total control over your production. The drag-and-drop tool can be used on the Siemens PLC and/or on your computer.

Our cobot workstations are safe to use without a fence. If required, it is always possible to safeguard with a simple combination of light curtains and two-mirror columns or a fence.

Specifications Cobot workstation SI-FAN25

|

|

Description |

Note |

|

Core System |

Fanuc Robot CRX-25iA |

– 7 movements/minute without fence – 10-12 movements/minute with fencework |

|

|

Frame with lift |

Stainless steel, including 2 pallet slots; max stacking height is 2300mm (incl. pallet height) |

|

|

Siemens PLC |

Program selection |

|

Infeed conveyer |

Roller conveyer |

Multipick |

|

|

Rotation possibility |

|

|

Intermediate sheet magazine |

400mm above indeed conveyor |

|

|

CRX 25iA cobot arm |

Reach 1889mm and Payload 25kg, incl. weight of the gripper |

|

|

Gripper |

In-house developed and produced grippers |

Standard: vacuum, fork or angle gripper Special: If a special gripper is needed for a specific product that can not be handled by our standard grippers, we can design and print a custom gripper with our 3-D printer All grippers are optionally available in your company colour |

Gripper specifications

|

|

Vacuum Gripper |

Fork Gripper |

Angle Gripper |

|

Payload |

25kg |

25kg |

25kg |

|

Multipick 2 or 3 |

possible |

possible |

possible |

|

Intermediate sheets |

possible |

possible |

possible |

Specifications Ultimate Palletiser SI-FAN20

|

|

Description |

Note |

|

Core System |

Fanuc Cobot arm CRX-20iA/L |

– 7 movements/minute without fence – 10-12 movements/minute with fencework |

|

|

Frame with lift |

Stainless steel including 2 pallet slots; maximum stacking height is 230mm (incl. pallet height) |

|

|

Siemens PLC |

Program selection |

|

Infeed conveyer |

Roller conveyer |

Multipick |

|

|

Rotation possibility |

|

|

Intermediate sheet magazine |

400mm above indeed conveyor |

|

|

CRX 20iA/L cobot arm |

Reach 1418mm; Payload 20kg, incl. weight of the gripper |

|

|

Gripper |

In-house developed and produced grippers |

Standard: 3-D printed vacuum, fork or angle gripper Special: if a special gripper is needed for a specific product that can not be handled by our standard grippers, we can design and print a custom gripper with our 3-D printer All grippers are optionally available in your company colour |

Gripper specifications

|

|

Vacuum Gripper |

Fork Gripper |

Angle Gripper |

|

Payload |

20kg |

20kg |

20kg |

|

Multipick 2 or 3 |

possible |

possible |

possible |

|

Intermediate sheets |

possible |

possible |

possible |

Specifications Cobot workstation SI-FAN10

|

|

Description |

Note |

|

Core System |

Fanuc cobot arm CRX-10iA |

– 7 movements/minute without fence – 10-12 movements/minute with fencework |

|

|

Frame with lift |

Stainless steel incl. 2 pallet slots; maximum stacking height is 2300mm (incl. pallet height) |

|

|

Siemens PLC |

Program selection |

|

Infeed conveyer |

Roller conveyer |

Multipick |

|

|

Rotation possibility |

|

|

Intermediate sheets magazine |

400mm above infeed conveyor |

|

|

CRX-10iA cobot arm |

Reach 1249mm; Payload 10kg, incl. weight of the gripper |

|

|

Gripper |

In-house developed and produced grippers |

Standard: 3-D printed vacuum, fork or angle gripper Special: if a special gripper is needed for a specific product that can not be handled by our standard grippers, we can design and print a custom gripper with our 3-D printer All grippers are optionally available in your company colour |

Gripper specifications

|

|

Vacuum Gripper |

Fork Gripper |

Angle Gripper |

|

Payload |

10kg |

10kg |

10kg |

|

Multipick 2 or 3 |

possible |

possible |

possible |

|

Intermediate sheets |

possible |

possible |

possible |

General information on cobot safety

The cobot works together with a person without fences. Combined use is only intended for non-hazardous applications, where the entire application, including tools, work object, obstacles and other machines, is free from significant hazards in accordance with risk assessment of the specific application.

If required, it is always possible to safeguard with a simple combination of light curtains and two-mirror columns or a fence.

Every user is obliged to perform a risk assessment and safety investigation for the application and to ensure that all required safety levels are enabled in the Cobot. The user shall perform this safety investigation or have it performed. The Ultimate Paletiser complies with the EU Machinery Directive.

For more information, please contact Max Calis or Annette Kimsma at +31 71 203 2160 or info@sica-packaging.nl.