Cobot workstations with Fanuc cobot arm

The cobot workstation is equipped with a Fanuc cobot arm. The Fanuc cobot arms are collaborative, industrial arms with a high payload capacity (choice of 10kg, 20kg or 25kg) and a long reach making these arms very suitable for various pick&place operations within production. For example, the cobot workstation can (de)palletize, casepack or any other pick&place operation.

Space-saving & safety

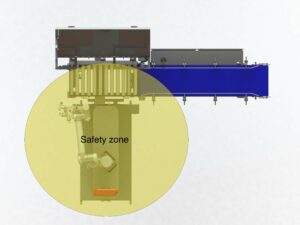

The advantage of a cobot system is that it is allowed to operate without fencing, thus saving a lot of space. Thanks to its sensitive and smart sensors, the cobot arm knows immediately when contact takes place with a person, after which it stops immediately. The workstation is restarted by simply pressing the "resume" button and proceeds with what system was doing.

Your next employee?

With our cobot workstation, you are assured of an employee who can work 365 days and 24/7. For example, palletizing is physically challenging for your human workers because of the physical intensity. The cobot workstation supports employees by taking over this task.

Solves your workforce shortage

The cobot workstation operates 24/7 365 days per year and is always on time.

Improve the ergonomics of your employees

Relieve your employees from doing injury-prone and monotonous tasks.

Save costs

By implementing a cobot working station you save on increasing salary costs.

More insight in your production

With our Production Insight Tool you get more insights in your production per line and you track down any potential inefficiencies

Characteristics

With our in-house software, automating has never been easier. Through the built-in drag-and-drop tool, you have complete control of the cobot workstation from your computer. If you want to add a new stacking pattern, just fill in the product specifications, select the right pallet, create the stacking pattern by placing the boxes (to scale) on the digital pallet, build the next layers and specify the direction of the labels and where to place any intermediate sheets.

Production Insight Tool provides the achieved KPIs of the cobot workstation. The tool gives you insight into your production output and allows you to compare lines and identify and resolve any inefficiencies.

The cobot arm is standard equipped with one 3-D printed gripper, a vacuum, angle or fork gripper, which is designed and produced in-house and can be customised in your company colour. If a special gripper is needed for a specific product that can not be handled by our standard grippers, we can design and print a custom gripper with our 3-D printer.

To be completely independent of the line, the cobot workstation has an integrated infeed. The feeder takes over the products at the end of the line and places the box at the fixed pick-up position. This allows you to easily and quickly place the system on other lines. The two openings at the bottom make it easy to lift and move the cobot workstation with the pump truck.

If desired, the cobot workstaiton can be equipped with an intermediate sheet magazine. The cobot workstation will then place its own intermediate sheet where necessary.

Specifications

Based on your production, we determine which Fanuc cobot arm is best for you. The cobot workstation can be equipped with the following arms:

- Fanuc CRX 10iA/L with 10kg payload (reach: 1418mm)

- Fanuc CRX 20iA/L with a load capacity of 20kg (reach: 1418mm)

- Fanuc CRX 25iA with a load capacity of 25kg (reach: 1889mm)

The speed of the cobot workstation depends on the operation. For palletizing, the cobot can place 7 products p/m with a single pick. If the weight and type of product allows, the cobot can pick 2 or 3 products at the same time. In that case, the cobot can place 14 or 21 products per minute. For case packing, it strongly depends on the distance between the pick-up position and where it needs to be placed. Feel free to contact us to discuss your case with one of our experts.

The cobot workstation is equipped with a pneumatically driven elevator. Depending on the product, the cobot workstation can stack up to 2300mm high.

The cobot workstation can be equipped with a vacuum, fork or corner gripper, depending on your products. For example, if you have only closed boxes then the vacuum gripper is the right version for you. If you have boxes with an open top or loose lid then the fork or corner gripper is the right gripper for you. We 3-D print our grippers ourselves and can easily make modifications based on your products.

If you need multiple grippers, switching between them is easy and quick. The cobot workstation indicates for each product program which gripper is required so that no mistakes are made here.

The cobot works together with a person without fences. Combined use is only intended for non-hazardous applications, where the entire application, including tools, work object, obstacles and other machines, is free from significant hazards in accordance with risk assessment of the specific application. If required, it is always possible to safeguard with a simple combination of light curtains and two-mirror columns or a fence. Every user is obliged to perform a risk assessment and safety investigation for the application and to ensure that all required safety levels are enabled in the Cobot. The user shall perform this safety investigation or have it performed. The Ultimate Paletiser complies with the EU Machinery Directive.

All our cobot workstations comply with the EU machinery directive.

Industries where we operate

Food

Beverage

Co-packing

Pharma

Petfood