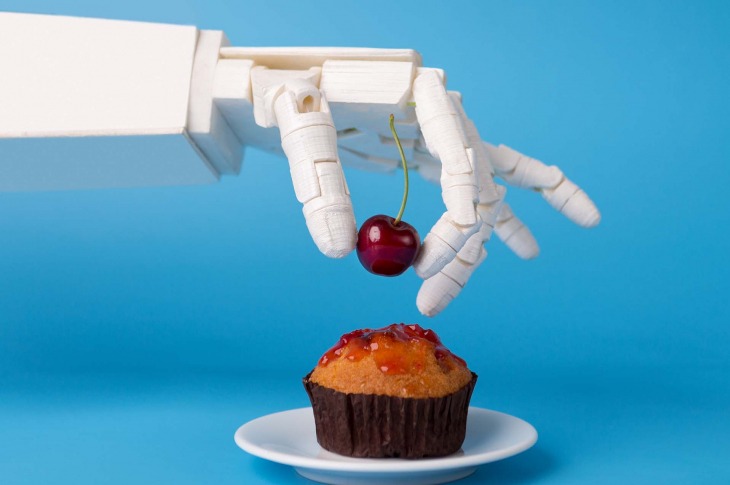

There are many reasons to move towards robotization. In this blog, we will briefly explain some of the reasons why food processing companies should do more with robotization and why now.

Wherever human hands are involved, there is a risk of contamination. This risk is reduced if you let robots take over the work. Food safety will therefore benefit. In addition, robots can work faster and shorten the production chain, because organizational and logistic steps can be skipped. Tracking and tracing is automatic in well designed robotized systems. This increases the transparency of the chain. In addition, food can be processed fresher and does not need to be frozen. This requires less energy in the production process, storage, transport and in the consumer’s home because they do not have to let it defrost. Robot lines can also work more compactly, so food can be processed closer to where it was harvested, caught, or slaughtered. All these reasons also lead to financial benefits for the industry.

In addition, working conditions in the primary process where every product is touched are not improving. Factories are becoming noisier, and productivity must keep rising. Production, for example, is increasingly taking place 24/7. In addition, the climatic conditions are poor: it is not unusual for production areas to be between four and seven degrees Celsius, because they work with fresh products. Better for general food safety, but not for the well-being of the employees.

In conclusion, robotization improves the safety and quality of food but also of the life of the people who make it. Not sure where or how to start? Let us help you. Contact us via info@sica-packaging.nl

Credits picture: https://www.gep.com